How to Choose the Right Warehouse Location in India for Maximum Growth

Logistics may be a nightmare to any company, be it a manufacturer, importer, or even a new online brand. You have an excellent product; the trouble is to deliver it to the customer.

It is not merely about how fast your truck is, the secret of success is where you begin. This is why choosing the right warehouse location in India is the most important decision you will make for your supply chain.

When your warehouse is not at the right place, two things go wrong:

1. High Costs: You spend too much money moving goods across the country.

2. Slow Delivery: Your customers will need to wait up to 5-7 days to have an order, and they may cancel.

This is a guide that makes it easier to select the best location to have your business.

Search Here

Recent Posts

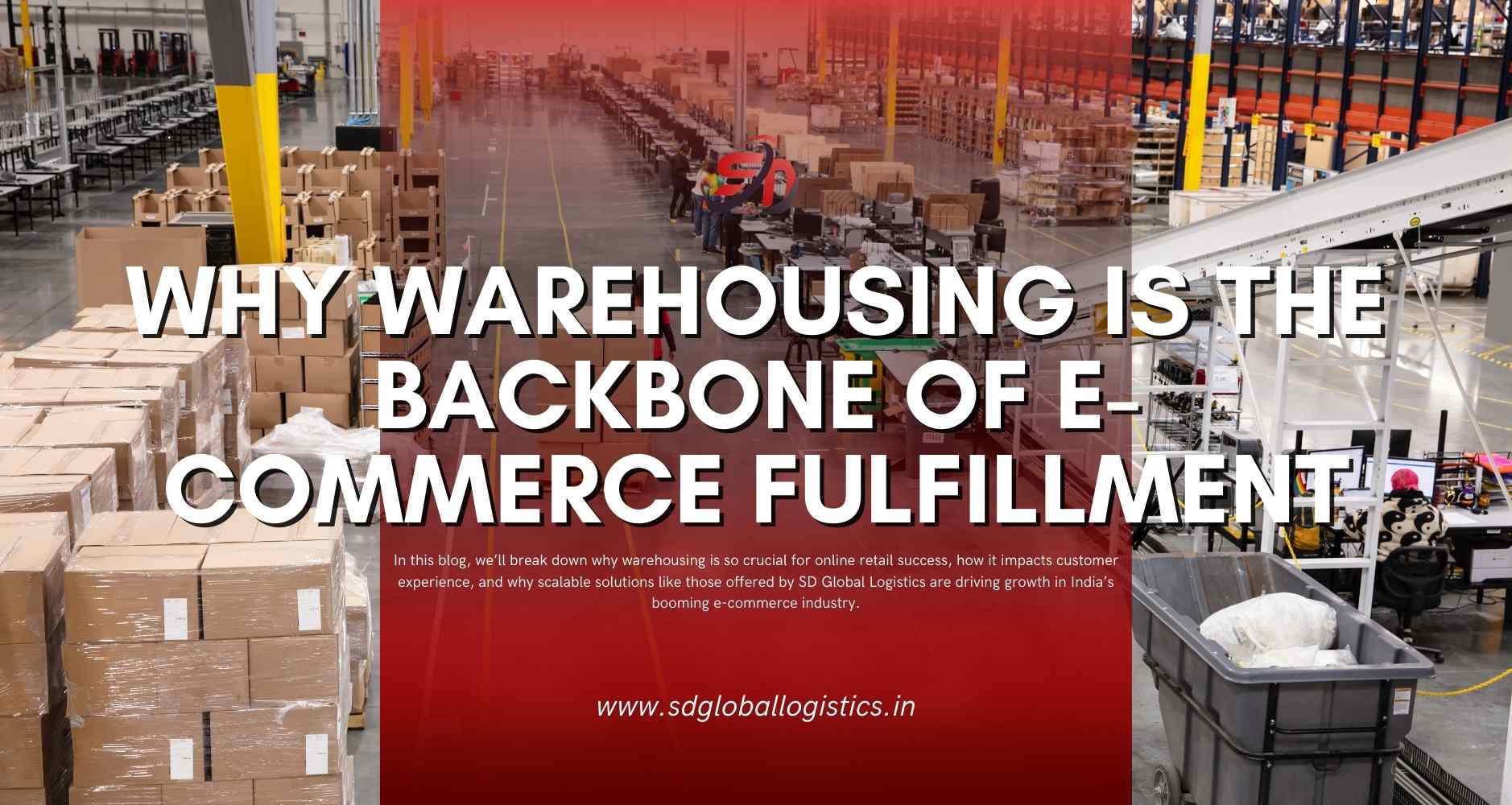

Why Warehousing is the Backbone of E-commerce Fulfillment

1. Follow Your Customers (The "Zone" Rule)

The first principle is straightforward, that is, keep your goods where your consumers are. In the past, companies would select a single large warehouse located in the heart of India and attempt to deliver everywhere. Today, that is too slow.

In case now you have the majority of your orders through South India, you need a warehouse in the South.

In case now you have the majority of your orders through South India, you need a warehouse in the South.

One location will not be enough in case you are selling across the country.

One location will not be enough in case you are selling across the country.

This is where multi-location warehousing comes in. Instead of one giant building, successful brands use a network of smaller fulfillment centers spread across different regions. This ensures that when a customer clicks "Buy," the product is already just a few hours away, making last-mile delivery fast and cheap.

2. Check the Roads and Connectivity

Without easily accessing in and out of the truck in a warehouse, there is no use of the warehouse. You should consider the logistical infrastructure of India.

When looking for a location, ask these questions:

Is it near a National Highway?

Is it near a National Highway?

Is it close to an airport or a seaport (if you import goods)?

Is it close to an airport or a seaport (if you import goods)?

For example, many companies choose a warehouse in Gurgaon not just because of the city, but because it sits right on major highways that connect to Jaipur, Delhi, and the rest of North India. It acts as a gateway.

Similarly, a warehouse in Delhi is often chosen because it is an urban hub, allowing for quick deliveries to millions of people within the city limits. Access to good roads means your product spends less time sitting in traffic and more time moving toward the customer.

3. Decide: Rent vs. 3PL Partner

This is a big decision. Would you rent your own empty building and employ your own personnel? Or should you hire a 3PL logistics provider ?

Rent Your Own: You rent and cover electricity, security and salaries. Even when business is slow, you pay full price. It is expensive and risky.

Rent Your Own: You rent and cover electricity, security and salaries. Even when business is slow, you pay full price. It is expensive and risky.

Outsourcing to a 3PL (Third-Party Logistics): You are contracting a company such as SD Global Logistics. They are already the owners of the warehouses, the personnel and the trucks. You just pay per space you utilize.

Outsourcing to a 3PL (Third-Party Logistics): You are contracting a company such as SD Global Logistics. They are already the owners of the warehouses, the personnel and the trucks. You just pay per space you utilize.

For most growing brands, using warehousing services in India provided by a 3PL is the smarter choice. It gives you immediate access to a pan India warehousing network without having to build it yourself.

4. Technology is a Must

Suppose that you had stock in three cities. And you are aware of the amount remaining? You are not able to make three different managers calls every hour. The right warehouse must have technology. Find a partner with an AI-based WMS (Warehouse Management system).

What it does: It is software that tracks every single item.

What it does: It is software that tracks every single item.

Why you need it: You can sit in your office and see exactly how much inventory you have in Mumbai, Kolkata, or Bangalore in real-time.

Why you need it: You can sit in your office and see exactly how much inventory you have in Mumbai, Kolkata, or Bangalore in real-time.

Proper inventory management technology prevents you from selling products you don't have (out of stock) or buying products you don't need (overstocking).

5. Compliance and Safety

Finally, is the warehouse legal and safe? Government rules in India are strict. You need to ensure the facility is a GST-compliant warehouse. This ensures your paperwork is smooth and you don't face tax penalties.

Also, consider what your product needs:

Dry Warehouse: Good for clothes, electronics, and furniture.

Dry Warehouse: Good for clothes, electronics, and furniture.

Cold Storage: Necessary if you sell food, chocolates, or cosmetics that melt.

Cold Storage: Necessary if you sell food, chocolates, or cosmetics that melt.

Security: Does the facility have cameras and guards?

Security: Does the facility have cameras and guards?

How SD Global Logistics Solves This for You

If this sounds like a lot of work to figure out on your own—don't worry. That is exactly what we do. SD Global Logistics is a leading supply chain and logistics partner. We do not merely give you space, we give you a strategy.

Network: We have network facilities throughout India. You are able to keep your goods closer to your customers instantly.

Network: We have network facilities throughout India. You are able to keep your goods closer to your customers instantly.

Scalability: Start with one city and scale to ten cities as you expand. We have a warehouse network that expands as you do.

Scalability: Start with one city and scale to ten cities as you expand. We have a warehouse network that expands as you do.

Tech-Enabled: With our systems, you are able to see everything that is in your stock.

Tech-Enabled: With our systems, you are able to see everything that is in your stock.

Conclusion

Choosing the right location isn't about looking at a map and guessing. It is about understanding where your demand is and finding a partner who can get you there. By moving your inventory closer to your buyers and using a professional warehouse services provider, you save money on shipping and delight your customers with speed.

Want to fix your logistics today? Contact SD Global Logistics to find the perfect distribution center in India for your business.